Description

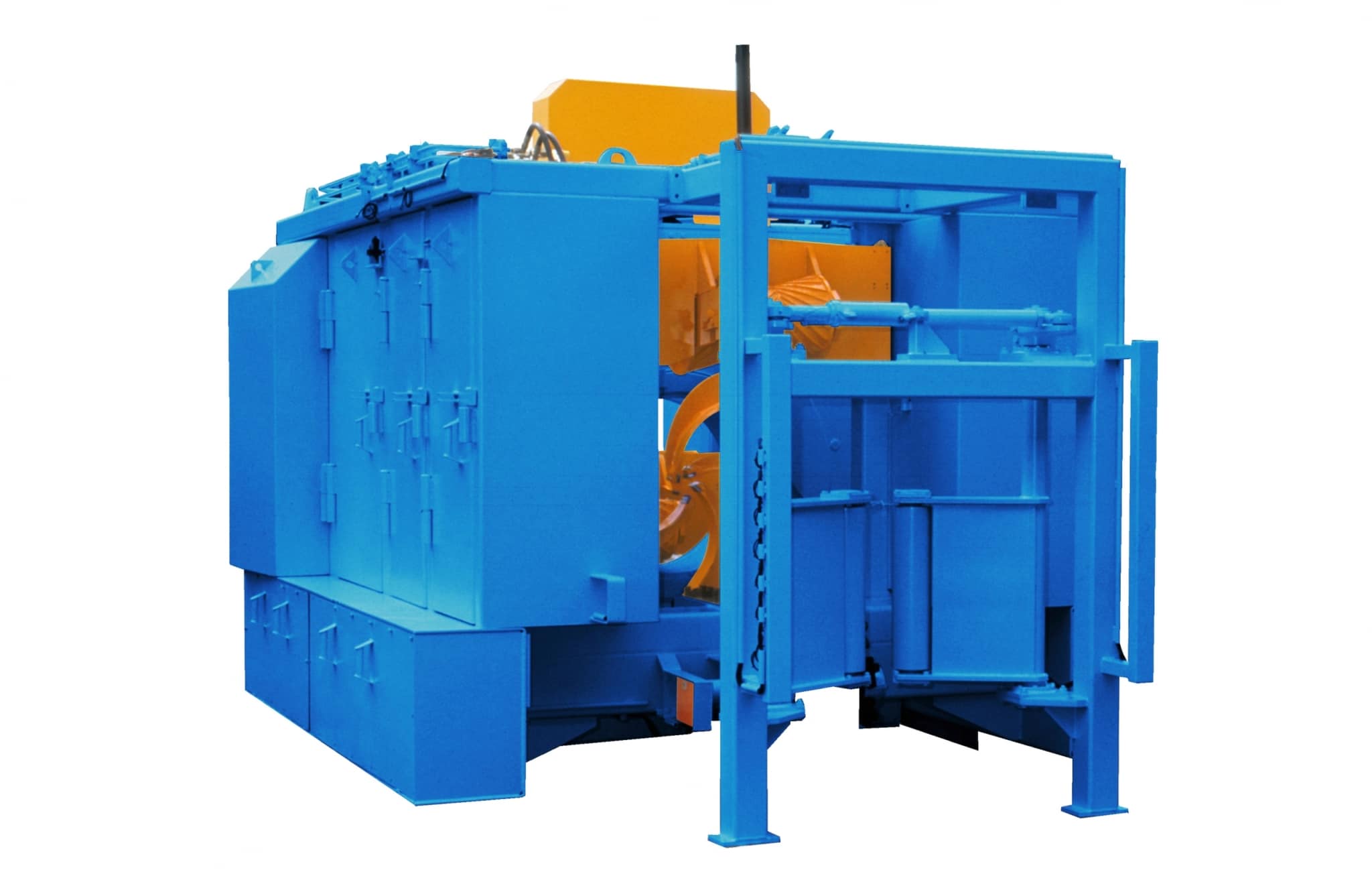

Debarker model VK1092

Valon Kone’s debarker model VK1092 is a rotor debarker for large logs. The VK1092 was launched in the 2000’s and it boasts the latest debarker model with a sliding rotor in the VK range At the same time it is the largest and the fastest debarker with a sliding rotor on the market. The machine is built to handle stress caused during debarking and handling large and heavy whole trees.

Debarking rotor

The VK1092 debarker is equipped with a debarking rotor (a sliding rotor), which is positioned according to log diameter and which has a diameter of 90 cm. The rotor is positioned hydraulically. The pneumatically pressed debarking tools (6 pcs) are installed on the infeed side of the rotor. The design of the tool arms makes them easier to open and minimises wood damage. The special design and the correct materials and production methods ensure the durability of the VK tool arms in any conditions.

The debarking tool tips that perform the actual debarking are made of durable hard metal. The tool tip is fastened to the arm with bolts, which means that it can be easily replaced. Different tool tip versions are available for debarking various wood species, for example.

Air seal for the debarking rotor

The air seal structure enables the debarking pressure to be adjusted during debarking. The air supplied by the compressed air network of the plant is led into the tool cylinders through an air seal inside the rotor. When the machine is empty of logs, the debarking tools hold just enough pressure to keep them closed (holding pressure). When the debarking tools climb onto a log, the pressure fed into the tool cylinders is quickly raised to the pre-set debarking level, when the debarking starts at precisely the right time. Once the log has passed the debarking tools, the system returns to the holding pressure level incrementally. The fact that the tool pressure can be adjusted makes it easier to maintain debarking quality during operation. The operator can use the control panel to one of three separate working pressure levels. Logs can also be stopped inside the debarker, as the pressurised air is automatically discharged from the tool cylinders when the log feeding stops. These features can only be found in debarkers equipped with the air seal technology.

Feedworks

Machines with a sliding rotor are always supplied without a centring VK infeed conveyor. The diameter of each log is measured before a log enters the machine, and this information is used to position the rotor at the correct height. The logs are always fed through the debarker at the same height and the position of the rotor changes according to log diameter.

In debarkers with a sliding rotor, the logs are fed through the machine using flight conveyors and pressure rollers. Particularly robust flight conveyors, which push the logs through the rotor, are mounted on both sides of the rotor. A set of two pressure rollers above both conveyors press the log against the flight chain preventing it from rotating during debarking.

When the machine is empty, the pressure rollers are shifted to the upper position to wait for the next log. The positioning is timed according to log diameter, taking into account the feed speed (measured by using a light screen at the front of the machine). The pressure rollers are positioned hydraulically.

A centring flap which guides the logs laterally can be installed at the front of the machine. This optional accessory is available for all VK sliding rotor models. It is particularly useful when debarking short logs.

On the tool side, the VK1092 debarker is protected on both sides by guard doors and the necessary safety guards that comply with all occupational safety requirements.

Technical Data

| Debarking diameter | 120 – 900 mm |

| Min. log length | 2.4 m |

| Weight | 25 000 Kg |

| Motor | |

| * rotor | 90 kW |

| * feedworks | 30 kW |